Necessity and Benefits of a Natural Gas Compressor

The demand for a gas compressor, especially a natural gas compressor, is on the rise. Choosing a compressor that has features and specifications for easy maintenance is much desired. Additionally, it is important to select an engine with a competitive edge in terms of natural gas compressor price over others in the market.

However, before you move on to the purchasing phase, it is important to understand what makes a gas compressor essential and how industries might benefit from it.

So, let us begin by taking a brief look at how natural gas is formed.

Formation of Natural Gas

A form of fossil fuel, natural gas is created deep beneath the earth's surface. It contains a substantial amount of methane along with other components like carbon dioxide, gaseous hydrocarbon liquids, and water vapor. A source of natural fuel that dates back millions of years, natural gas is formed from animal and plant matter and is found in the spaces and cracks between rock layers beneath the oceans and earth. The gas is drawn out of these stores and passed through an intricate pipeline system for compression, storage, and transportation via direct pipelines or tanks.

The Role of a Natural Gas Compressor

Companies use natural gas compressors to decrease the total gas volume and make transportation and distribution easier. Different kinds of natural gas compressors are used at various stages within the pipeline, from extraction to distribution and all the way until it reaches the end customer. This is because the distance of travel and friction might result in the gas losing pressure.

A natural gas compressor reduces the volume of gas by increasing its cumulative pressure. This is done for two main reasons:

- • To utilize the attendant decrease in volume and pressurization to transport natural gas via pipelines to be distributed to large areas. This includes pipeline distribution or transportation to consumers.

- • To bring down the volume of natural gas and store greater quantities in bottles or tanks for transport or storage.

Impurities present in natural gas, like particulates and moisture, make it essential to process and filter the gas before it enters a natural gas compressor. The gas might be subjected to alternate heating and cooling within the machinery. This causes any hydrocarbon liquids and water in the natural gas to condense, which subsequently dries out.

Why Are Gas Compressors Necessary?

A natural gas compressor makes use of filtration units and inside components to compress and process natural gas easily. Prior to compression, this process rids the gas of any extra particulate or liquid elements.

The gas compressed at the station stays free of all additives while being processed and transported to the end market. When the supply of gas has a reduced volume, is clean, and has enough pressure, it can stream through the pipelines easily and reach end users. The extracted drip gas or liquids can be used in several other applications.

Depending on the actual compression of natural gas, some stations require several processing units to lift gas pressure to its needed level.

Cleaned gas is passed through various stages of compression with more than one unit. The compression stations remove and prevent further pressure problems with the distribution of gas. As an outcome, the natural gas sustains its flow even after passing through multiple pipelines and gradually exiting the system. This guarantees an ideal flow for gas supply and transports it to its end consumer.

Benefits of a Natural Gas Compressor

Natural gas compressors effectively and safely extract and transfer gas to the end customer, sometimes over considerable distances. The primary benefits of a natural gas compression engine include the following:

- • Filtration and Separation

Filtration and separation of natural gas are essential parts of the compression process. It removes any and all forms of impurities from the gas and maintains its high quality. The process involves the use of gas compressor filters at more than one point throughout the gas pipeline. The gas can collect condensation while it travels, which is later filtered out to preserve the purity of the gas.

- • Distribution of Gas

Once the natural gas store is accessed, compression assists the upward flow of gas from wells into the distribution network or storage. The compression used while transporting natural gas is often a boon for the distribution system.

- • Sustains Consistent Pressure

When gas pipelines stretch over major distances, varying terrain elevations can lead to differences in the air pressure. Compression engines used along the pipeline ensure a safe and consistent pressure of the gas when it is transported. It provides the perfect piping size to maintain this pressure while being moved in greater amounts.

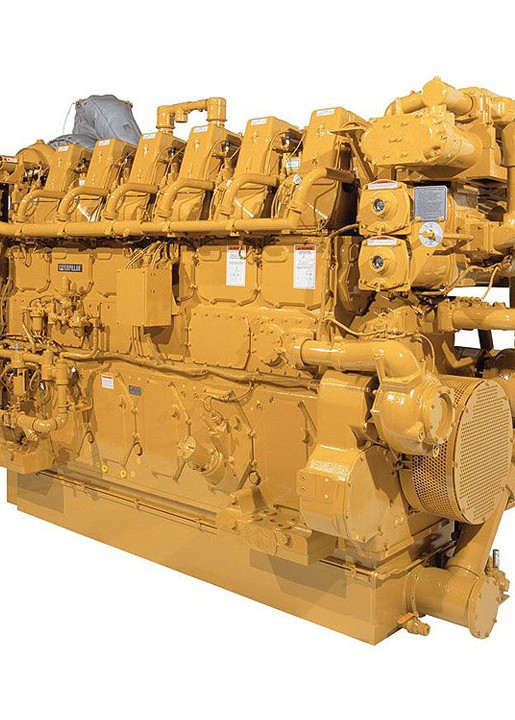

Why Choose a CAT Gas Compression Engine?

Gas compression engines from CAT are the main movers for gas gathering, gas lift, pipeline compression, wellhead compression of gas, gathering, storage, and re-injection. These engines come in a competitive natural gas compressor price range as compared to other engines in the market. This provides the machines with an economic edge in addition to efficiency.

Caterpillar has an impressive power and fuel range, with the lowest operating rates in the entire industry. Check out the finest of CAT gas compression engines at https://www.gainwellindia.com/cat/products/new/Oil-Gas/Gas-Compression-Engine.

xcvcxv